Magnetic Belt Conveyor: A Revolutionary Answer for Efficient Materials Dealing with

BusinessMagnetic Belt Conveyor have actually become an vital resource in industries that need the efficient motion of products, particularly in settings where products need to have to be carried rapidly and also securely. These conveyors combine magnetic pressures with standard waistband transportation units to deliver distinct advantages, like the capacity to handle ferrous components and also maintain an efficient flow of goods. A magnetic belt conveyor is actually equipped along with magnetics placed below or along the conveyor district, which entice magnetic components, enabling all of them to be properly relocated along the assembly-line production. This functions makes it particularly helpful in business such as manufacturing, reprocessing, food items processing, and mining, where transferring metallic things successfully is important. The advantage as well as effectiveness of magnetic belt conveyors have made all of them a go-to solution for functions that demand heavy hauling or dealing with materials that are actually complicated to move with conventional bearers.

Some of the key advantages of magnetic district bearers is their ability to efficiently deal with iron materials. Ferrous steels, such as iron, steel, and also other magnetic steels, are actually generally made use of in numerous business however could be difficult to transfer without customized tools. Magnetic conveyors are developed with magnets embedded either in the belt itself or even below the area of the conveyor, which create a magnetic intensity that draws in and also firmly secures onto these metals. This makes certain that metal components, fragment, and materials are relocated effortlessly and also without the risk of them dropping or even being changed during transportation. This ability to securely have products without the need for manual work or even facility managing makes magnetic belt conveyors very useful in environments like recycling vegetations or even metalworking centers where steels require to be actually relocated effectively and also securely.

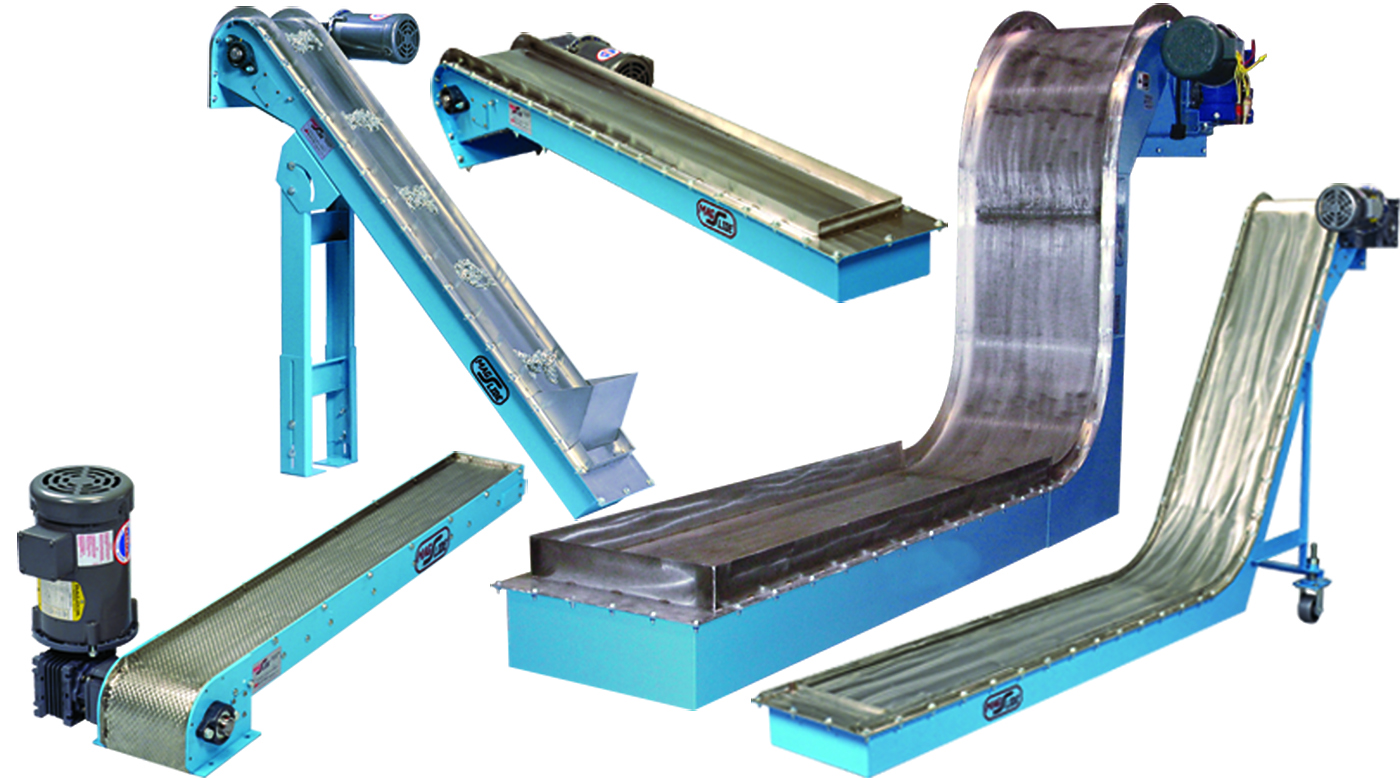

An additional considerable advantage of Magnetic Belt Conveyor is their adaptability. These bearers may be actually made to run in different positionings as well as arrangements, relying on the certain needs of the procedure. Whether components require to be actually relocated flat, up and down, or even at an incline, magnetic conveyors could be individualized to satisfy the assembly line’s design. Additionally, various forms of magnetics may be utilized to create magnetic intensities along with varying staminas, making it feasible to carry materials of different measurements and body weights. The usage of electromagnets, for example, allows the toughness of the magnetic intensity to become readjusted as needed, supplying flexibility when managing different iron components. This adaptability helps make Magnetic Belt Conveyor suitable for a large variety of treatments, from small production to sizable recycling procedures.

The efficiency of Magnetic Belt Conveyor is another aspect that sets all of them in addition to typical bearers. Making use of magnets allows a continuous flow of materials, lowering the likelihood of disturbances in development. Unlike various other bearers that may need constant adjustments or upkeep to deal with different products, magnetic conveyors offer a even more stable and also dependable methods of transporting iron items. The smoothness of the operation indicates that there is a lot less weathering on the device, which lowers the need for repair work and also stretches the life of the devices. In fast production environments, this consistent, trustworthy activity of products is actually crucial for sustaining productivity and minimizing downtime. The productivity of magnetic district conveyors helps make sure that functions rush properly and also components are relocated swiftly and also safely through the manufacturing procedure. To gather supplementary details kindly look at Tecnimetal

Another significant perk of Magnetic Belt Conveyor is their reduced maintenance requirements. Unlike standard bearers that rely upon rubbing to move materials, magnetic district conveyors use the magnetic force to handle metallic things, lowering the damage on the district itself. This implies that the belt experiences much less friction as well as, consequently, much less damages in time. Therefore, businesses profit from far fewer replacements of deteriorated components, which reduces servicing costs. Magnetic Belt Conveyor are also simple to tidy, with their parts made for very easy disassembly and servicing. In fields like food handling, where cleanliness is actually a concern, Magnetic Belt Conveyor may be set up to become washed rapidly and also effectively, guaranteeing conformity with health standards.

Protection is actually an additional vital factor where Magnetic Belt Conveyor stand out. Several industries manage unsafe products, sharp metallic things, or products that might pose a risk to workers. By utilizing magnetic bearers, companies can easily automate the managing of these items, lessening the necessity for manual work as well as the linked threats. As an example, in reusing vegetations or even steel handling centers, workers might need to have to handle sharp junk metallic, which might create injuries if messed up. Magnetic bearers get rid of the need for workers to actually touch these hazardous products, decreasing the likelihood of mishaps. Furthermore, due to the fact that magnetic conveyors keep materials safely and securely in location, there is actually a lowered threat of spills, contamination, or product imbalance, additional enhancing the protection of the working atmosphere.